Factory Sales 8T/H SUS304 135-150℃ UHT Pasteurizer Machinery For Milk

Product Descripyion

Direct steam injection sterilization, often referred to as DSI sterilization, is a common method used in laboratories and healthcare settings to sterilize equipment and materials. This process involves injecting saturated steam directly into a chamber containing the items to be sterilized. DSI sterilization is effective in killing a wide range of microorganisms, including bacteria, viruses, and spores.

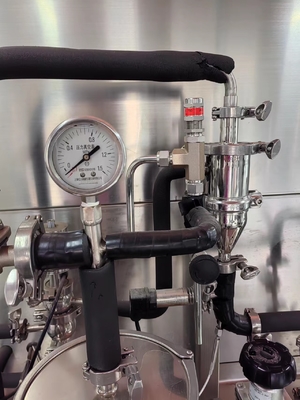

DSI sterilizer machine

Working Principles

1. Steam Injection:Steam is injected directly into the product or material, ensuring rapid heating.

2. Temperature and Pressure Control: The control system maintains the required temperature and pressure to achieve sterilization.

3. Sterilization Cycle: The duration of the cycle is carefully controlled to ensure that all microorganisms, including spores, are destroyed.

4. Cooling: After sterilization, the product or material is cooled down before being handled or further processed.

| Capacity |

30L/H |

| Powder |

13kw |

| Pipe Pressure |

5.0Mpa |

| Material Inlet Temperature |

10-30℃ |

| Material Heating Temperature |

140℃ |

| Material Sterilizer Time |

5s/30s |

| Material Outlet Temperature |

20/30℃ |

Sterilizer Key Components

PLC——Siemens

* Temperature control accuracy: ± 0.3 degrees;

* The temperature difference between materials and media △ t ≤ 5 degrees;

* The control panel is centrally controlled and can be connected to a computer for control;

* The experimental data can be printed, recorded online, downloaded, automatically generated for curve analysis, and permanently

saved.

Direct steam injection device

* The structure of DSI steam sterilization device and flash cooling device is complex, and there are high requirements for the configuration of pump valves, electrical components, and other equipment.

* The amount of steam injected during the flashing process determines how much steam needs to be removed during the flashing cooling process. Keep the material composition unchanged.

Our Service

We have long-term cooperation with many professional freight companies and shipping companies. Our workers also have a lot of shipping experience. Before the product is shipped, the installation and layout will be discussed strictly according to the size of the equipment to ensure that the space of the container can be fully utilized under the premise of ensuring the safety of the equipment. After the goods are loaded into the truck, we also use special freight straps to fix the equipment in the container to avoid the wear and tear caused by the collision of the equipment during transportation.

FAQ

Q: What products is this equipment typically used for?

A: Mainly used for milk/coffee liquid/juice, etc.

Q: Can samples be tested in advance?

A: Yes, the customer provides raw materials and formulas and we can help with testing.

Q: What are the advantages of experimental sterilizers?

A: The most advanced DSI sterilization process, DSI and tubular sterilization processes can also be used interchangeably.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!